Variable Frequency Drive Basics (Working Principle)

Variable Frequency Drive (VFD) Basic Configuration

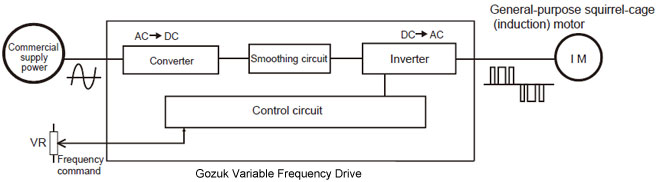

The basic configuration of a variable frequency drive is as follows.

Fig. 1 Basic configuration of variable frequency drive

Each part of a variable frequency drive has the following function.

Converter: Circuit to change the commercial AC power supply to the DC

Smoothing circuit: Circuit to smooth the pulsation included in the DC

Inverter: Circuit to change the DC to the AC with variable frequency

Control circuit: Circuit to mainly control the inverter part

Principle of Converter Operation

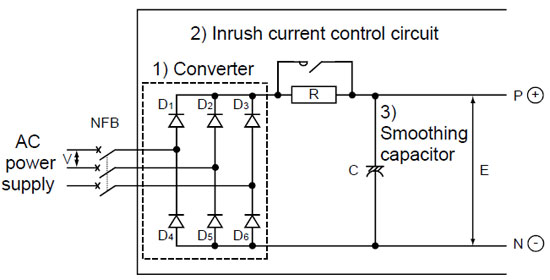

The converter part consists of the following parts as following figure shows:

- Converter

- Inrush current control circuit

- Smoothing circuit

Fig. 2 Converter part

Method to create DC from AC (commercial) power supply

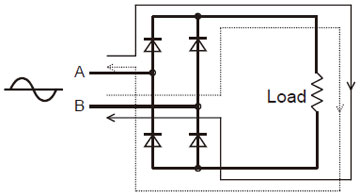

A converter is a device to create the DC from the AC power supply. See the basic principle with the single-phase AC as the simplest example. Fig. 3 shows the example of the method to convert the AC to the DC by utilizing a resistor for the load in place of a smoothing capacitor.

Fig. 3 Rectifying circuit

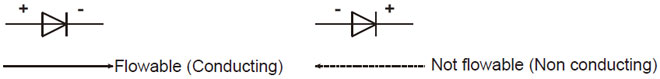

Diodes are used for the elements. These diodes let the current flow or not flow depending on the direction to which the voltage is applied as Fig. 4 shows.

Fig. 4 Diode

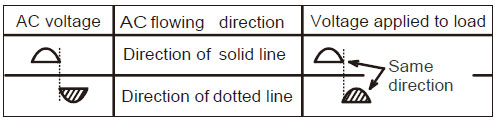

This diode nature allows the following: When the AC voltage is applied between A and B of the circuit shown in Fig. 3, the voltage is always applied to the load in the same direction shown in Table 1.

Table 1 Voltage applied to the load

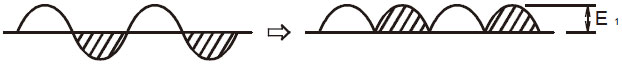

That is to say, the AC is converted to the DC. (To convert the AC to the DC is generally called rectification.)

Fig. 5 (Continuous waveforms of the ones in Table 1)

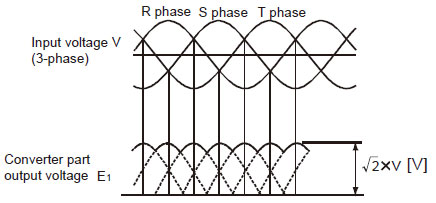

For the three-phase AC input, combining six diodes to rectify all the waves of the AC power supply allows the output voltage as shown in Fig. 6.

Fig. 6 Converter part waveform

Input current waveform when capacitor is used as load

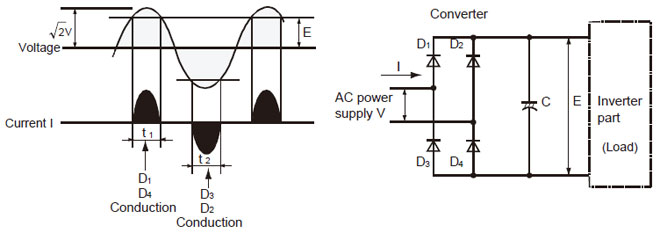

The principle of rectification is explained with a resistor. However, a smoothing capacity or is actually used for the load. If a smoothing capacitor is used, the input current waveforms become not sine waveforms but distorted waveforms shown in Fig. 7 since the AC voltage flows only when it surpasses the DC voltage.

Fig. 7 Principle of converter

Inrush current control circuit

The basic principle of rectification is explained with a resistor. However, a smoothing capacitor is actually used for the load. A capacitor has a nature to store electricity. At the moment when the voltage is applie